Custom Diamond and cBN Grinding Wheels

Coastal Diamond is a leading manufacturer of superabrasive cutting and grinding wheels serving the US and International markets. Proudly made in the USA, our Diamond and cBN Grinding Wheels are bonded using a proprietary system that helps you achieve maximum performance and keeps you ahead of your competition.

Used for: Ceramics – Quartz – Composites – Graphite – Steels – Carbide – Blade & Knife Sharpening

Coastal Diamond Advantages

- Part integrity and consistency

- Increased wheel life

- Highly efficient grinding performance

- Range of operations from rough grinding to honing

- Wet or dry grind operations

- Ease of workability for operator

- Cost effective

- Decreased scrap

Resin Bond Grinding Wheels

Resin bond is the most versatile of all bonding systems. Resin bond grinding wheels are formulated for specific grinding applications.

Learn more

Metal Bond Grinding Wheels

Metal bond grinding wheels are manufactured using a variety of metal fillers with Diamond or CBN abrasive. Generally, Metal Bond wheels have the hardest matrix, and require coolant.

Learn more

Electroplated Grinding Wheels

Electroplated grinding wheels are and excellent option when an aggressive amount of stock removal is required.

Learn more

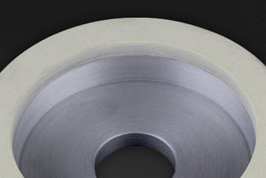

Vitrified Grinding Wheels

Vitrified grinding wheels have enabled polycrystalline tool fabricators to obtain excellent surface finishes, quickly and productively.

Learn more

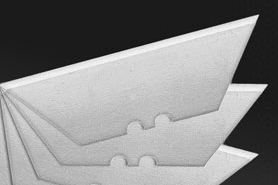

Razor Blade Grinding Wheels

Razor blade grinding wheels can reduce manufacturing costs and scrap, and increase manufacturing capacity by increasing line speeds

Learn more

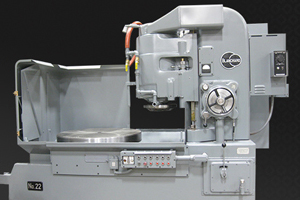

Blanchard Grinding Wheels

Effective when you need to grind alloy steels; specialty steel, ceramic, or composite parts; or fabrications of exotic materials, such as aircraft parts using Blanchard Grinder.

Learn more

OD Grinding Wheels

OD Grinding Wheels use the best combination of abrasive, bond structure, and bond type to help you optimize your grinding operation. Made to order for your specific needs.

Learn more

ID Grinding Wheels

ID Grinding Wheels use the best combination of abrasive, bond structure, and bond type to help you optimize your grinding operation. Made to order for your specific needs.

Learn more

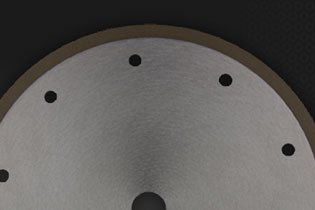

Carbide Cut Off Wheels

Cutoff wheels in different diameters and diamond layer widths, for both wet and dry cutting applications

Learn more

Surgical Sharpening

The ultimate edge is the one in a surgeon’s or technician’s hand and CBN is the ideal material to use to prepare it.

Learn more

Diamond Core Drills

Diamond core drills use a special blend of metals mixed with the matching diamond to form a matrix resulting in superior performance.

Learn more

Ewag Grinding Wheels

We have been designing wheels to replace many OEM wheels for Ewag Grinding Machines. We can help make you more productive today!

Learn more

Vollmer Grinding Wheels

Keeping a sharp edge can be achieved with a Vollmer Grinding Wheel machine. Using a Coastal Diamond wheel will help you go the extra mile.

Learn more